VPS Containers

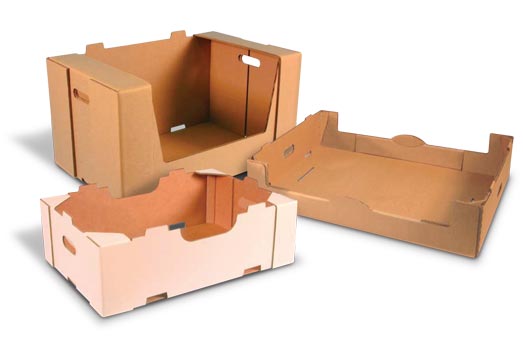

Our VPS® series of enclosed and open containers and trays are a performance-focused design solution with tremendous stacking strength, excellent material economy, custom design features, and multiple merchandising options – all in a single-piece construction. Fully customizable to meet your product and customer demands, the VPS 5, 10, and 30 open containers and trays are all designed to match the standard common footprint system used within the produce industry.

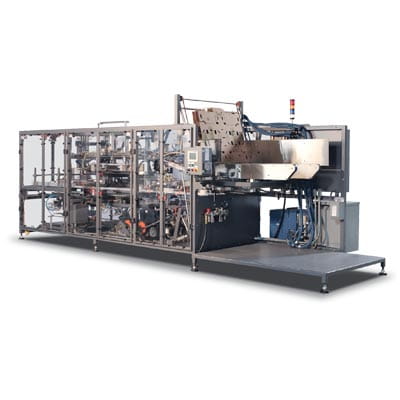

Automation in your operation is critical and most VPS products are erected on automatic machinery to streamline your operation and manage costs. Superior stacking strength provides additional opportunities to reduce package and product damage through distribution and maximizes branding impact at the point of sale.

Applications

- Club store displays

- Fresh and fresh cut produce

- Fresh and processed meats

- Cheeses

- Bakery

- Bag in box & flexible packaging products

- Plus many more

VPS 5 Containers

The VPS 5 design offers the greatest amount of flexibility within the VPS family and an excellent use of material. The VPS 5 is ideal for heavy items needing extra protection and stacking strength in a display ready format.

Ideal applications include:

- Produce

- Bag in Box products

- Fresh Meat

- Frozen Food

- Dry Goods

- Stand up Pouches

- Bread/Bakery Products

- Bottled Liquids

- Bulk packed products

Consider using the VPS 5 if you want to:

- Improve Distribution Performance

- Reduce Damage

- Use less material, reduce package costs

- Reduce labor and Workman compensation costs (through automation)

- Maximize merchandising impact

VPS 10 Containers

The VPS 10 has been designed to move easily from the shipping to retail environment, offering excellent stacking strength, custom interior corner features and a variety of merchandising options – all in a single piece construction. The VPS 10 features a 100% “open top” merchandising display tray with a patented design that creates double wall thickness with dual stacking corners for excellent stacking strength.

Box depths range from 3 to 7 inches and ideal applications include products in the shallower ranges such as fresh produce, case ready meat trays, bakery or any other product where layer separation for protection is desired.

Consider using the VPS 10 if you want to:

- Improve performance

- Reduce damage/shrink

- Increase merchandising impact

- Improve pallet stability

VPS 30 Containers

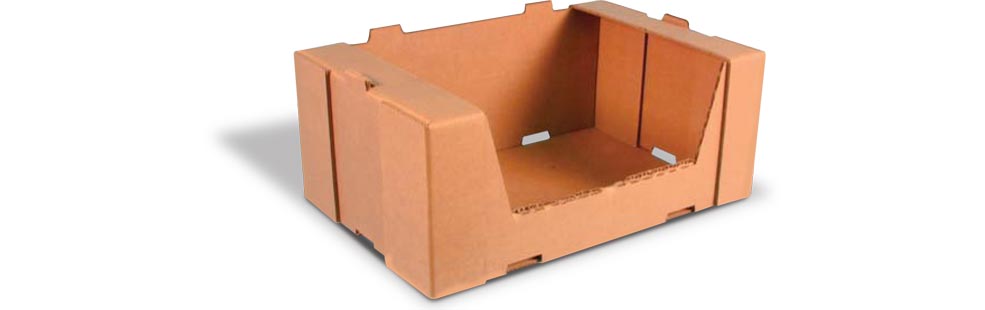

The VPS 30 is designed to provide maximum product protection through the distribution environment to retail and is ideal for heavy items needing extra stacking protection and the added benefit of a full or partial lid. WestRock’s VPS 30 is available in modular and custom footprints and in a variety of depths for bulk and multi-layer product formats.

VPS 30 is a patented, lidded traypack, designed essentially as a full overlap end or side load tray with two separately articulating top flaps. The unique design effectively doubles the number of vertical stacking corners. It is particularly appropriate for the Fresh Meat and Fresh Produce industries.

Consider using the VPS 30 if you want to:

- Improve distribution performance

- Reduce damage

- Use less material and reduce costs

Features and benefits include:

- Superior stacking strength: Eight integral, cross laminated corners provide superior stacking strength over most conventional lidded packaging designs constructed of the same material

- Versatile one piece construction

- May allow the use of lighter weight materials that facilitate fiber and cost reductions

Contact

Get started.

How can we help you meet your business goals? Contact a member of our team to learn more about our products and services.