How package design improved user experience and reduced waste for Valvoline

In the beginning, Valvoline oil came in tin cans. Today, vintage motor oil cans are considered antique collectibles, and a rare Valvoline one-gallon can from this era could be valued at hundreds to thousands of dollars depending on the condition.

Well-known as a high-performance auto brand, especially in the racing world, Valvoline motor oil is actually older than the consumer car itself.

Founder Dr. John Ellis started the company in 1866 to provide a lubricant for steam engines, and it became the first U.S. trademarked motor oil brand as well as the recommended motor oil for the first mass-produced car, the Ford Model-T.

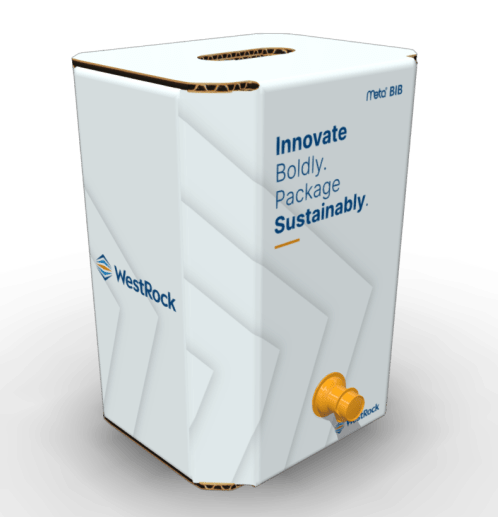

Not wanting to rest on its laurels, today Valvoline Global Operations continues to find ways to innovate. Recently, in partnership with WestRock, the team figured out how to put its oil in a box. You read that right – oil in a box.

First it came in a can, and with the prolific use of plastics, that became the new standard. But a box? Oil and paper seem to go together about as well as oil and water. But when the team began to address some prolonged usage issues, Valvoline Global Principal Packaging Engineer Steven Ruble thought maybe the box could be the answer the company was looking for. After all, it worked for wine.

“WestRock was already supplying boxes to one of our plants, and I saw the Meta machine (Meta 150 Case Former) at Pack Expo. I was intrigued by the stack-ability of the eight-sided bag-in-box (Meta BIB). So, that’s what drew me in initially.”

The problems with petroleum packaging

Besides being the leading producer and distributor of motor oil, Valvoline Global also supplies oil to global, national, regional and independent retailers and auto service centers, including national big box retailers that provide auto service within their storefronts. Many of these service centers were having the same issues.

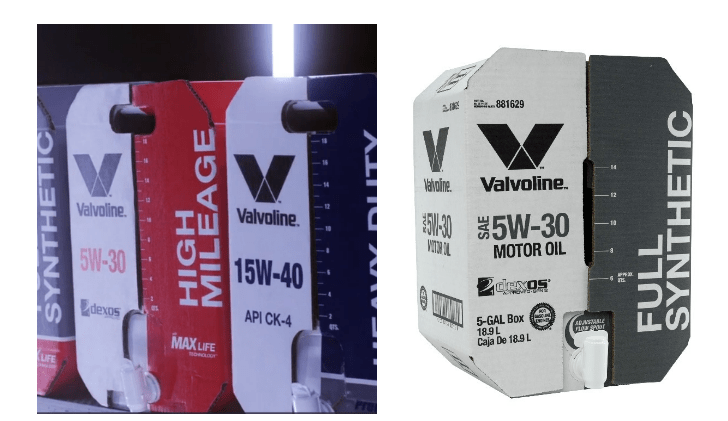

Different cars require many different oil blends. When a service center agrees to service any car, that means it needs to keep in stock all the blends required by all the different cars on the road. That leads to some inventory issues when a product only comes in 55-gallon drums or five-quart and one-quart plastic bottles.

No service center has space to store large steel drums for every type of oil. That means it has to purchase cases of five-quart jugs or one-quart bottles. Since the average oil change requires four to six quarts of oil and an express shop might perform 90 to 100 oil changes in a day, technicians have to keep a significant amount of single-use plastic containers on site. And once those containers are out of the case, they can be shelved but not stacked.

Before the bag-in-box innovation, the only purchase options for auto service centers were 55-gallon drums or bottles holding five quarts or a single quart.

Additionally, big box retailers had a need to differentiate the containers being sold in their stores versus the ones being used in their service centers. Having trouble keeping up with inventory when there are so many types of oil in use, service centers often run out of a certain blend. And when that happened at a service center within a big box storefront, it was easy for auto technicians to run into the store to grab what they needed, causing a larger inventory nightmare.

Valvoline Global knew these issues weren’t going away. It’s not like car companies would all of a sudden agree to design all of their cars to run on the same type of oil. The team needed to find a way to create containers that would hold more oil, be easy enough to lift, and be able to be stacked. Those containers also needed to look vastly different from what was being sold to average consumers; big box retailers needed the ability to know how much of their product was getting pulled into their service centers.

Thinking outside inside about the box

Already connected to WestRock, Ruble contacted the team to learn about Valvoline Global’s options. “The 8-sided- bag-in-box came up again as a possibility and so we started looking at the advantages that gave us, namely stack-ability.”

The octagonal shape of the Meta box can make it stronger than traditional 6-sided boxes, meaning the design could increase the chance that Valvoline’s large, heavy boxes wouldn’t experience flex-cracking or crushing in the corners when stacked. Achieving greater strength would also allow box manufacturers the opportunity to use a lesser grade of corrugated board, which means less fiber could be used, making the boxes more cost effective and less wasteful.

“And they’re easier to handle. Unlike a steel drum, you don't need a forklift to move them around. Somebody can put it on the back of a pickup truck and deliver ten of them pretty easily,” said Ruble.

Could filling a box fulfill all the requirements?

Valvoline Global’s initial bay box system design combined the Meta BIB with reusable containers.

Based on a design for a bay box system that Valvoline Global envisioned (above), the WestRock team went to work on initial design options for a six-gallon bag-in-box, producing several for them to choose from. Besides a new box design, Valvoline Global envisioned fitting the box into a bay shelving system that service centers could use to store and properly dispense oil from the boxes.

The system included reusable containers that could be positioned under the boxes to dispense oil and then be used by auto technicians to perform oil changes.

“We based our original concepts on the Meta-8 design with various iterations, including a seven-sided design. The concepts included varying flap styles, sizes, shapes, spout locations, access holes, and sight windows for viewing oil levels,” said WestRock Lead Designer Kevin Simpkins.

For the bay system to work and for easy storing and transport, the company had many more requirements for the new boxes, including:

- Fully automated box forming, bag loading and sealing.

- The ability to evacuate as much oil as possible from the bag.

- Durability for warehouse distribution and handling and storing on pallets.

- Creating an ideal fit so the bag inside isn’t too tight but doesn’t leave too much room inside the case.

- Reducing bulge and box weakening due to the nature of bagged liquid.

- The ability to easily break down boxes and recycle them.

- Visual appeal and ease of identifying the type of oil inside the bag, as well as how full it is.

The initial design process took three months of cooperation, narrowing down options and making small adjustments until both sides felt they had a box that met all of their requirements.

“This was one of the first BIB (bag-in-box) projects where I was involved from the very beginning and had the luxury of working together with our customer and their suppliers to help put together a complete process side by side. Every aspect of the project could be fine-tuned by all teams as it was developing and being implemented,” said Simpkins

Working out the kinks … literally

Once they were complete with the design phase, the testing phase revealed the team had some more work to do. The six-gallon box was still a bit heavy to lift. Many stores don’t want employees lifting over 40 pounds and the six-gallon boxes were approaching 50.

Handlers also reported some box bending and crushing when stacking and some bulging caused by turbulence, or excessive air bubbles created during the bag filling process. Switching to a five-gallon box would put the weight around 40 pounds and could also address the problems with crushing, so they made the change.

The team also discovered that one of the reasons boxes weren’t holding up is because of the way handlers were stacking the boxes. People were stacking them in storage the same way they stacked them in the bay, on the short side, when it was meant to be stacked on the long side. Poor user experience was causing box failure.

To address the issue, the team tried adding arrows to show how the box should be stacked, but it didn’t make a difference in how people chose to stack them. The change that made the difference: removing the handle altogether.

“The design team was really good with bringing different ideas to the table. The whole team helped with innovation and improvements from Ray, our salesperson, to Jeff and the equipment team in Orlando,” said Ruble.

Results: better inventory, more efficiency, less waste

A happy biproduct of creating this inventory solution for auto service centers was helping them with something else: single-use plastic waste. A five-gallon box uses one plastic bag to hold 20 quarts of oil. If a shop that uses cases of one-quart containers switches to the bag-in-box solution, the plastic reduction is significant.

“A five-gallon bag with dispensing tap has only 10 percent of the plastic, by weight, of 20 one-quart bottles with caps. That’s a 90% reduction in plastic.” said Ruble.

The reduction is an important one for Valvoline Global as a company working to find solutions to the world’s plastic waste problem. It’s a founding member of the National Lubricant Container Recycling Coalition, an industry group focused on creating and finding the best ways to recover and recycle plastic lubricant containers.

WestRock is a global industry leader in paper-based packaging. If you’re looking for a competitive alternative to plastic or need to solve a packaging problem, we have solutions for a variety of products across many industries. Contact our team to learn more about your options