Rap-A-Mat®

WestRock’s wraparound machines are designed to provide efficient product accumulating and loading utilizing semi- and fully-automatic systems that require less operator labor and corrugated fiber. Whether using an RSC, FOL, POL or tray, these tightly formed, compact packages deliver high-performance stacking ability, reduced shipping movement, and material savings.

The Rap-A-Mat Wraparounds collate products directly from the packaging line – up to 25 cycles per minute, and enable size change-overs in less than 15 minutes. This solution is ideal for small can, bottle and carton items as well as large, difficult-to-package items.

Features & Benefits

- Low-level blank magazine sensor

- Fully-automatic product accumulating, loading, and sealing operation receives products directly from production line

- Allen-Bradley® programmable controller with complete diagnostics

- Top-quality, brand-name, heavy-duty, industrial-grade components

- State-of-the-art hot melt adhesive system with 24-hour/7-day glue timer

- Heavy-duty indexing; AC variable frequency, main drive

- Clear Lexan® interlocked guard doors utilized throughout

- Clean, open design provides easy access for all maintenance functions

- Venturi vacuum system used for improved reliability, lower noise level, and less costly maintenance

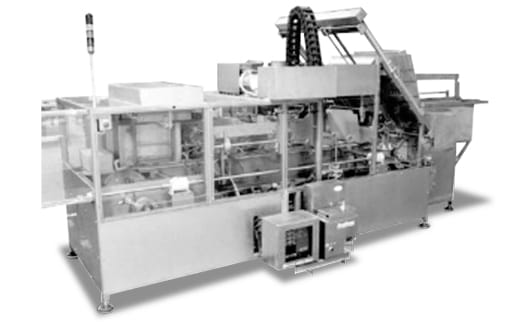

Rap-A-Mat 398

Utilizing a flat scored and slotted corrugated blank, the Rap-A-Mat 398 automatically feeds and forms blanks into the loading station. Product is collated into the proper packing patterns, automatically loaded onto the blanks, and tightly wrapped around the product. The case is transferred to the compression section, sealed and discharged onto the conveyor.

- For all industrial uses

- Fully-automatic product accumulating, loading, and sealing operation receives products directly from production line

- Up to 25 cycles per minute

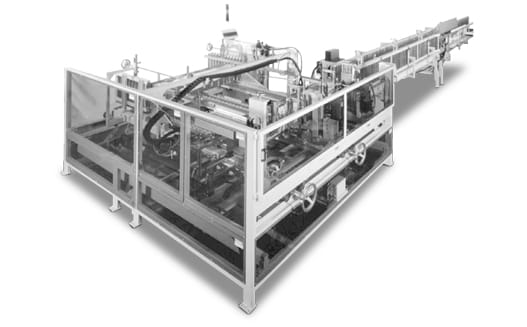

Rap-A-Mat 400

The Rap-A-Mat 400 allows for automated wraparound packaging and sealing for large, difficult-to-package products shipped in shallow, narrow or end-sealed packages.

- For long, narrow products such as shelving, fluorescent lighting fixtures and unassembled furniture

- Semi-automatic operation reduces labor costs and increases output for unusual packages

- Wraparound blanks reduce materials by up to 25%

- Up to 12 cycles per minute depending on operator speed and package size

- Size change-over under 20 minutes

Contact

Ready to learn more?

Our team of experts is ready to talk about your packaging needs. Contact us today.