The secret to a successful, sustainable e-commerce business: automated packaging

At WestRock, helping our customers win means developing new packaging innovations that enhance relationships between brands and their customers, while also being good for the environment. Automation might not be the first thing that comes to mind when you think of sustainability, but it is a core element of WestRock’s approach and essential to supporting business value for any organization navigating the e-commerce channel.

Packaging that is right-sized, eliminates void fill, reduces dimensional weight and can be automated to accelerate throughput—that’s how machinery promotes sustainability.

When right-sized is the right choice

“In addition to making innovative fiber-based packaging, WestRock designs systems to improve the efficiency and sustainability of the whole manufacturing process,” said Patrick Kivits, president, Corrugated Packaging at WestRock.

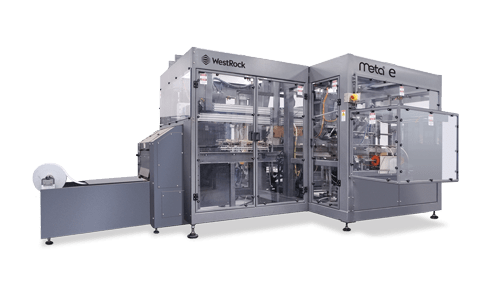

WestRock’s Automated Packaging Solutions (APS) business develops machinery that produces custom, on-demand packaging accurately sized for any product type.

Optimizing manufacturing efficiency while leveraging fiber-based packaging, which in many cases is curbside recyclable, is a formidable one-two punch to promote sustainability. But central to both machinery and the product portfolio is protecting products in transport.

Right-sizing packaging system capabilities, like Box On Demand® and BoxSizer™, enable our customers to create the right size box for every product, every time, which allows them to save on labor costs, reduce packaging waste and lower their transportation carbon footprint. The Meta® e corrugated case, designed to block and brace products with a cohesive paper, eliminates plastic void fill, protects products and provides the benefit of speed.

“Many customers come to us looking to reduce or eliminate void fill and reduce their overall packaging and shipping costs,” added Rick Anderson, vice president, Automated Packaging Solutions. “Our right-sizing solutions not only solve those challenges, but they also provide our customers with a more sustainable package being delivered to their customers.”

Speed and efficiency on demand

Customers often report that on-demand packaging systems improve their labor and factory logistics. For manufacturers packing and shipping products that vary in size, the old way required them to keep stacks of ready-fold corrugated boxes on the shop floor to be manually opened, taped, packed and shipped. Systems like Box On Demand and BoxSizer make it possible to not only produce right-sized boxes for each order, but also to do it faster with less labor. Many customers report an increase in the number of direct-to-consumer shipments per day, reduction of floor space from stored corrugated boxes and cost savings from reduced packing labor costs and decreased waste – all of which help our customers win in e-commerce.

“Generally, when we install a machine, our customers see an immediate gain in efficiency and throughput,” Rick explained. “This allows them to ship orders faster while using less packaging. We’ve found over and over that using less packaging helps our customers save money, increase consumer satisfaction and reduce their impact on the environment.”

“WestRock and e-commerce have this in common,” Patrick adds. “Neither can be relegated to being simply ‘about boxes.’ It’s about getting product out the door in a more efficient, sustainable way. Our on-demand platforms accomplish that, which is a real win for customers.”